A monolithic slab is made by pouring a single layer of concrete to create a slab and footing for a build. One of the advantages of the monolithic slab over other foundation forms is the shorter amount of time and resources needed to complete the build. It is also a superior process compared to traditional foundation systems.

The Applications

As an example, garage monolithic slab foundations are one of the most common applications for the mono slab foundation. For detached garages and commercial steel buildings, the monolithic foundation is a great choice to ensure speed and cost effectiveness with your build, without compromising on strength or qualityThe Process

The top of the footing of the slab is connected to a concrete foundation wall, then to load bearing walls. The concrete footing forms the anchor to hold the slab solidly in place. The monolithic slab form, helps to minimize the thickness of the wall, width of the base and also minimizes seismic effects. When used correctly, the monolithic pour is as effective as stem walls, which typically require three pours. Since forming a monolithic slab is one pour, it greatly reduces labor costs.The footing being poured to stretch under the frost line, makes this system a frost protected shallow foundation, and prevents damage from freezing and thawing. Monolithic slab rebar makes sure there are no gaps and the slab maintains its shape. There are various building forms for monolithic slabs, but the ones using a void are the best at resisting changing temperatures and soil content.

Having this type of foundation is more energy efficient, compared to a basement or crawl space. That equals less space for you to heat or cool. The monolithic slabs constructed with void forms can be made with either styrofoam or plastic, but plastic is more favorable due to being made with recycled materials and create less environmental waste.

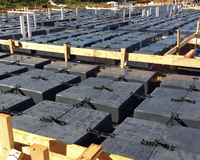

The highest quality monolithic slab system available today is Wafflemat. Wafflemat uses plastic void forms, made from recycled materials that accommodate for expansive soils. The Wafflemat system is one of the fastest and strongest foundation systems you can build.

You can build a Wafflemat system in four easy steps:

- Level the Build Site

- Lay Plastic Vapor Barrier

- Arrange WaffleBoxes to meet engineer specifications

- Pour Concrete

For a more in-depth knowledge on how to build your Wafflemat foundation, contact a Wafflemat expert today for a free, step by step walkthrough for your next build project.